Wine Vineyard Fabrication

STI/SPFA 2014 Tank of the Year

| Product / project title: | Vineyards |

| Product / project owner: | PRIVATE |

| Product / project location: | St. Helena, CA |

| Date completed: | August 2014 |

| Construction standard (if any): | ASCE 7 |

| Overall height / length (feet, inches): | 31’ -0” |

| Column height (feet, inches): | 8’ -0” |

| Diameter (feet, inches): | 10’ -0” |

| Capacity (US gallons): | 12,300 |

| Steel tonnage used (US tons): | 9.5 |

| Steel thickness (inches): | 0.135 – 3/16” |

| Product/Project Description: | |

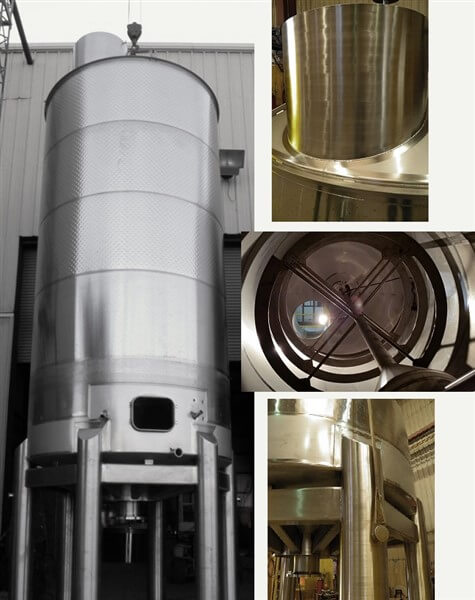

| In the process of producing red wine, extraction of color and tannins is a vital step. Under traditional winemaking procedures, this extraction is time consuming. A process developed in Europe, Flash Détente now allows the winemakers to extract the desirable compounds from the skins prior to fermentation, a step that reduces cycle time and increases product throughput. Flash Détente is the current version of the traditional thermovinification method. In this method, the crushed and de-stemmed grapes are rapidly heated to around 180°F, then the heated grapes are processed in a vacuum flash cooling system where the temperature is rapidly lowered to 86°F. The rapid cooling sequence causes an intercellular explosion in grape skins that produces the desired color and characteristics in an improvement over the traditional thermovinification method. | |

| In order to process grapes in the Flash Détente process, the grapes must be processed in a mixer tank capable of maintaining a homogeneous gelatinous emulsion of the juice and solids. This tank was specially designed to accommodate a high torque, low speed internal mixer. To interface with existing winery equipment, this tank was required to be mounted on legs at 8 feet above the floor. | |

| The tank is located in a region subject to high seismic loads, so a substantial foundation, anchorage and support structure was required to resist the ASCE 7 design loads. Additionally, the tank must support the substantial mixer loads, both gravity and torque loads. The support of the mixer and mixer shaft required close tolerance fabrication of the mixer support structure and guides. The tank is constructed entirely of Type 304 stainless steel. | |